English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

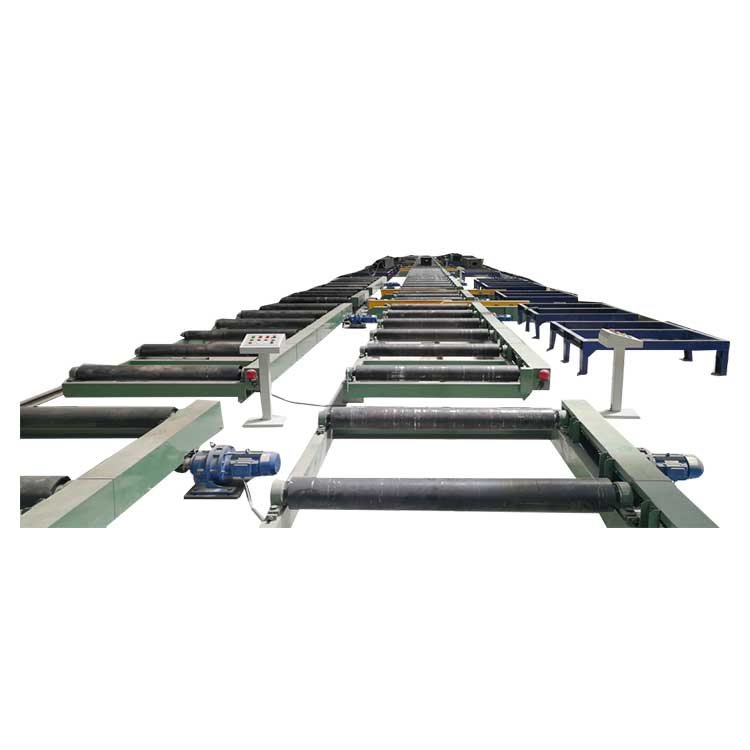

Roller Tables1

Send Inquiry

Roller tables are high performance equipment in the line to produce box beam, which is manufactured by JINFENG WELDCUT who is the professional China manufacturer and supplier of Roller tables with affordable price. The Roller tables provide more safety and high efficiency for moving the beams between each working stations for the Box beams production.

JINFENG WELDCUT will provide have 1 year warranty for the Roller tables. The main electric elements of the Box beam production lines are selected from the world famous brand that will bring more convenient for Users to find the parts in local without getting from long distance from China. The Roller tables are the most advanced and high efficiency equipments to increase the productivity for End-users from steel structures, steel construction and high building.

Structure view

EQUIPMENT USAGE

It is mainly used for conveying workpieces from working stations to next working station.

MAIN TECHNICAL PARAMETERS

|

1 |

Box beam section size |

300~1500mm |

|

2 |

Box beam length |

6000-15000mm |

PERFORMANCE CHARACTERISTICS

The conveying roller tables is composed of a roller rack, a roller drum, a sprocket, a chain, a bearing seat, a cycloidal pin wheel reduction motor, and a foundation height adjustment mechanism that are integrally welded from section steel. It has the advantages of high bearing capacity and smooth transportation. The roller adopts a double support structure on one side, which has stronger impact resistance;

(Internal structure of roller)

Roller tables installed in Users’ factory