English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

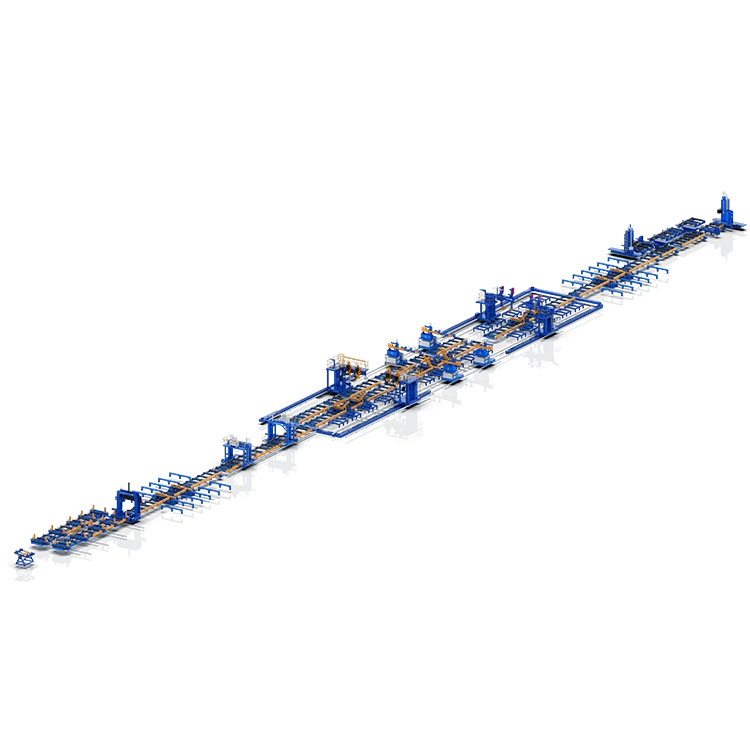

Box Column Welding Lines

JINFENG WELDCUT will provide have 1 year warranty for the Box column welding lines. The main electric elements of the Box column productions are selected from the world famous brand that will bring more convenient for Users to find the parts in local without getting from long distance from China. The X15 Automatic Box column welding lines are the most advanced and high automation production lines to increase the productivity for End-users from different industries.

Send Inquiry

JINFENG WELDCUT will provide have 1 year warranty for theBox column welding lines. The main electric elements of theBox column productions are selected from the world famous brand that will bring more convenient for Users to find the parts in local without getting from long distance from China. The X15 AutomaticBox column welding lines are the most advanced and high automation production lines to increase the productivity for End-users from different industries.

Specifications

|

Model |

X12 |

X15 |

|

Box column size |

300-1200mm |

300-1500mm |

|

Plate thickness |

10-60mm |

10-60mm |

|

Box column length |

6000-15000mm |

6000-15000mm |

|

Max weight ofBox column |

≤30t (15000mm) |

≤30t(15000mm) |

|

Welding types |

1-Tack welding by CO2/MAG in manual |

|

|

2- Back welding by CO2/MAG in auto |

||

|

3- Electro-slag welding in auto (ESW) |

||

|

4- Full welding by SAW (submerged arc welding) |

||

|

Baffle assembling machine |

1 set |

|

|

Box column assembling machine |

2sets (one for U type assembling, one for box assembling) |

|

|

Electro-slag welding machine |

2sets, wire consumable type |

|

|

CO2/MAG back welding machine |

2sets |

|

|

CO2/MAG filling welding machine |

2sets |

|

|

Submerged arc welding machine |

2sets, tandem arc welding technology |

|

|

End-face milling machine |

1sets |

|

|

Beam flipper 180°overturn |

2sets(4pcs), Loading 15Tons/set |

|

|

Beam flipper 180°overturn |

5sets(10pcs), Loading 30Tons/set |

|

|

Steel cart |

1sets (3pcs), Loading 30Tons/set |

|

|

Roller tables |

~160 meters |

|

|

Support data collection for MES |

||

Feature And Application

1.The X15 Box column welding lines are high automation production lines to produce the welded Box column columns with lesser workers and lesser cranes.

2.The line can be fully integration with the MES system and complete the real-time communication between the upper computer and the control system, complete the data collection of the equipment, upload all collected data to the factory MES system (or the upper centralized control system), and ensure the timeliness and effectiveness of information transmission.

3. The design and protection must meet the requirements of relevant national standards and environmental protection; Equipment safety and protective devices must meet relevant industrial standards;.

4.This Box column welding lines are widely used in steel construction and steel structures, for welding Box column columns for steel construction building, high level building and steel structures, or bridges etc.

5. The flexible design of the welding equipment allow to support any brands of the welding power sources.

6. CE, ECA certificated are available.

7. This line provide the production from light duty beam to very heavy duty beam with big thickness without changing any tools or equipment.

8. From the assembling to the end-facing the whole processing no need any cranes except the loading at the beginning and unloading in the end, which reduce greatly the risk of using cranes.

The list of the machines and equipment to established a whole production line to produce welded box-beam:

1- Baffle assembling machine

This machine is a special equipment for the assembly and positioning welding of the reinforcing rib plate in the inner cavity of theBox column. It is the preferred product for steel structure enterprises that produce theBox column workpiece to reduce labor intensity and improve work efficiency.

2- Box column assembling machine

The box column assembly machine is the key equipment for the production of Box column (column), which mainly completes the assembly of Box column (column) work piece. This machine is one of the necessary equipment for steel structure enterprises to produce box girders.

One machine for U type assembling.

One machine is for Box type assembling.

3- Electro-slag welding machine

XZHB15 cantilever electroslag welding machine is an excellent product launched by Jinfeng Welding and Cutting Company for the steel structure industry. It is a special welding equipment specially designed for welding Box column. In order to ensure sufficient rigidity and torsion resistance during Box column fabrication, baffles (i.e. stiffer plates) are generally welded on the inside of the Box column. This machine is a special equipment for welding the welds between the outer plate of the Box column and the inner baffles.

4- CO2/MAG back welding machine

XQHB15L series Box column cantilever gas shielded welding machine is a special welding equipment specially designed for backing welding of Box column (column) and filling welding after backing, which is launched by our company based on market demand and years of experience in developing steel structure equipment.

5- CO2/MAG filling welding machine

XQHB15 series Box column cantilever gas shielded welding machine is a special welding equipment specially designed for backing welding of Box column (column) and filling welding after backing, which is launched by our company based on market demand and years of experience in developing steel structure equipment.

6- Submerged arc welding machine

XMHB15 box girder cantilever submerged arc welding machine is an excellent product launched by Jinfeng Welding and Cutting Company for the steel structure industry. It is a special welding equipment specially designed for welding large and medium-sized Box columns (columns). Over the years, after continuous optimization and improvement, the performance has become more perfect.

7- End-face milling machine

With the rapid development of economic construction, construction, bridge and other industries have increasingly strict requirements for the quality of steel structure engineering. The butt joint of H-beam,Box column and column, and slender parts, and the end face processing of the work piece have become an essential process. The end face processing not only greatly improves the quality of the work piece, reduces the on-site installation and construction errors, shortens the construction period, and improves the on-site construction efficiency. It also brings better economic benefits to steel structure enterprises. According to the actual processing situation of steel structure enterprises, our company is absorbing the advantages of similar products internationally, and timely launched new products to meet the market demand. It is not only used in the steel structure industry, but also can be used as general equipment, widely used in bridge, electric power, oil, petrochemical and other machinery manufacturing industries.

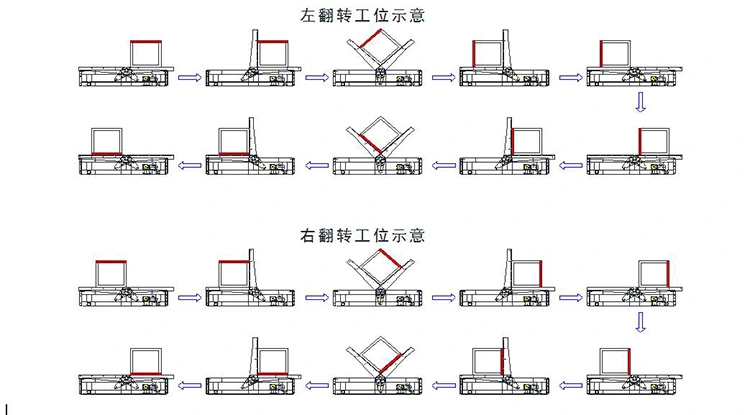

8- Beam flipper 180°overturn

Two pieces of mobile 180 ° hydraulic beam flippers are used for turn-over of work pieces welded on one side. When working, lift the work piece away from the roller table or work-piece rack, and the reducer drives the two beam flippers to move synchronously to move the work piece to the side of the roller table or work-piece rack, and then two hydraulic cylinders drive the two arms to rotate synchronously, move the work piece to the middle of the roller table or work-piece rack after overturning, and then transport the work piece to the next process or welding.

According to the actual situation, two pieces can be used separately as a group to flip the short beam. At the same time, 4 pieces can also be combined into one group for the overturning of long beams. High flexibility and efficiency.

The working flow chart of beam flippers:

9- Steel cart

This equipment is mainly used to coordinate with the production process to move the work piece from the conveying roller table or other equipment to the equipment to be processed. The steel cart mainly has two action functions: walking and lifting. The displacement of the work piece can be completed through manipulation and control. The equipment has simple structure, convenient operation and stable operation. The machine adopts heavy-duty design, with a maximum load of 30 tons;

10- Roller tables

It is mainly used for conveying workpieces from the assembly of Box column to the completion of welding, end facing.

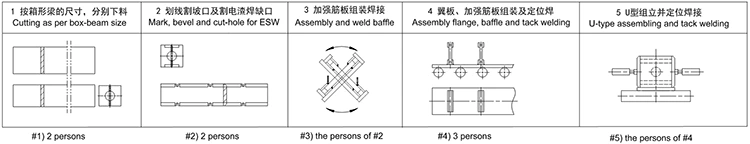

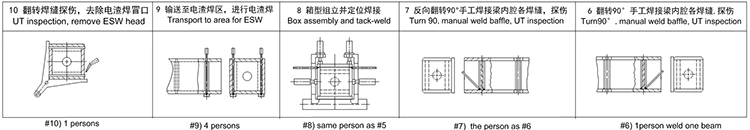

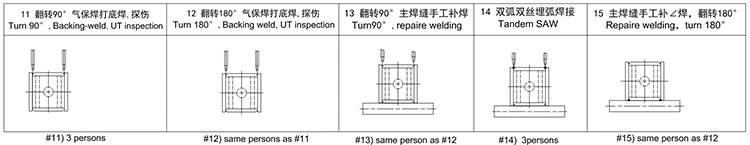

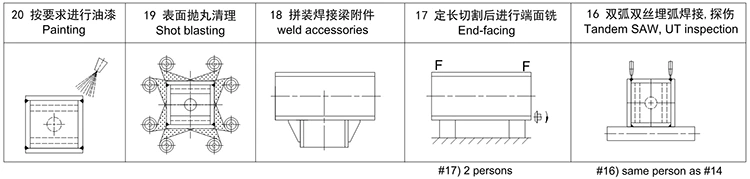

How to produce a welded Box column from steel plate?

Following is the production flow chart for the production from plates till H beam and final inspection.

Production flow chart