English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Box Column CO2 Back Welding Machines

Send Inquiry

Box column CO2 Back welding machines

Box column CO2 Back welding machines are high performance equipment in the line to produce Box column, which is manufactured by JINFENG WELDCUT who is the professional China manufacturer and supplier of Box column CO2 Back welding machines with affordable price. The Box column CO2 Back welding machines provide more safety and high efficiency for assembling the plates in U shape and Box shape that needed for the Box columns production.

JINFENG WELDCUT will provide have 1 year warranty for the XZHB15 Box column CO2 Back welding machines. The main electric elements of the Box column production lines are selected from the world famous brand that will bring more convenient for Users to find the parts in local without getting from long distance from China. The Box column CO2 Back welding machines are the most advanced and high efficiency equipments to increase the productivity for End-users from steel structures, steel construction and high building.

Structure view

Specifications

|

NO. |

MODEL |

XQHB15 |

|

|

1 |

Box column width |

□300~□1500 mm |

|

|

2 |

Box column height |

□300~□1500 mm |

|

|

3 |

Box column length |

6000~15000 mm |

|

|

4 |

Rail length |

19000 mm |

|

|

5 |

Rail span |

1400mm |

|

|

6 |

Welding speed |

Depending on welding technology |

|

|

7 |

Air pressure |

0.6~0.8 MPa |

|

|

8 |

CO2 pressure |

0.1~0.3 MPa |

|

|

9 |

Welding wire diameter |

As per requirements of welding power source |

|

|

10 |

Control way |

Variable frequency stepless speed regulation |

|

Feature And Application

XQHB15 Box column CO2 Back welding machines is an excellent product launched by Jinfeng Welding and Cutting Company for the steel structure industry. It is a special welding equipment specially designed for welding large and medium-sized Box columns (columns). Over the years, through continuous optimization and improvement, the performance has become more perfect, and is deeply welcomed by customers at home and abroad, with a relatively high market coverage. The device has the following advantages:

4.1.1 The machine adopts AC frequency conversion speed regulation with a wide speed adjustment range to meet the needs of different welding speeds. Fast return speed and stable operation.

4.1.2 Adopt a heavy-duty welding tracking device to make the weld more uniform and smooth;

4.1.3 High degree of automation, reliable operation, simple structure, and convenient operation and maintenance;

4.1.4 The electrical control system is installed inside the column, integrating the electric control box, operation panel, and column, which is not only concise and beautiful, but also very convenient to operate.

Box-beam CO2 Back welding machines installed in Users’ factory

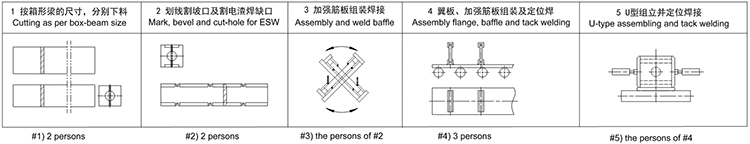

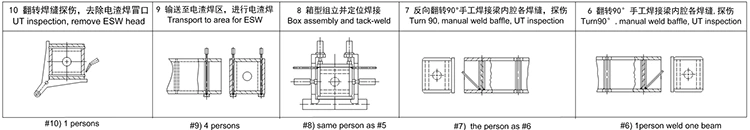

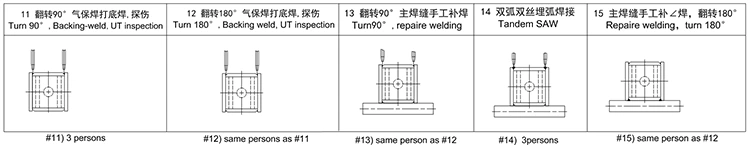

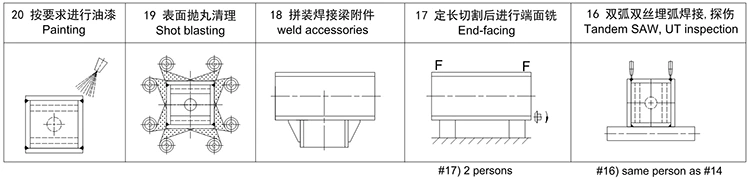

How to produce a weldedBox column from steel plate?

Following is the production flow chart for the production from plates till H beam and final inspection.

Production flow chart