English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Box Column Assembling Machines

Send Inquiry

JINFENG WELDCUT will provide have 1 year warranty for the XXZ15 Box column assembling machines. The main electric elements of the Box column production lines are selected from the world famous brand that will bring more convenient for Users to find the parts in local without getting from long distance from China. The XXZ15 Box column assembling machines are the most advanced and high efficiency equipments to increase the productivity for End-users from steel structures, steel construction and high building.

Specifications

|

1 |

Box column width |

□300~□1500 mm |

|

2 |

Box column height |

□300~□1500 mm |

|

3 |

Box column length |

6000~15000 mm |

|

4 |

Rail length |

19000 mm |

|

5 |

Rail span |

2500 mm |

|

6 |

Main machine moving speed |

0.5~4 m/min |

|

7 |

Working pressure of hydraulic system |

12 Mpa |

|

8 |

Maximum pressure of side cylinder |

15t×2 |

|

9 |

Maximum pressure of upper cylinder |

21t×2 |

|

10 |

Drive mode |

Double sided variable frequency drive |

Feature And Application

XXZ15 Box column assembling machines have the following advantages:

The Box column (column) is composed of a "U" shaped beam and a cover plate that have been spot welded and formed. During assembly, the workpiece is stationary, the main machine moves in sections, and the clamping assembly mode is positioned as required.

First, lift the "U-shaped" spot welded to the conveying roller table of the assembly machine or transport it to this station from the previous "U-shaped" assembly station. Then, lift the upper cover plate onto the "U-shaped" according to the drawing requirements, and use it as a host side pressing device and an upper pressing device. Press and spot weld the upper cover plate to complete the assembly of the entire workpiece. The assembly of segments of a workpiece in length is achieved by the moving position of the host machine. The assembled workpiece is sent to the next process by the conveying roller table for further processing.

(The manual CO2 MIG welding machines here are supplied by User.The manual welding machines are not in the supply range of Seller/supplier)

Box-beam assembling machines installed in Users’ factory

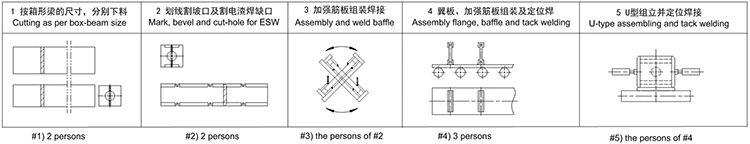

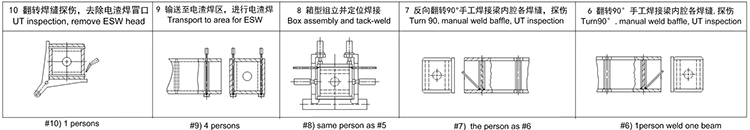

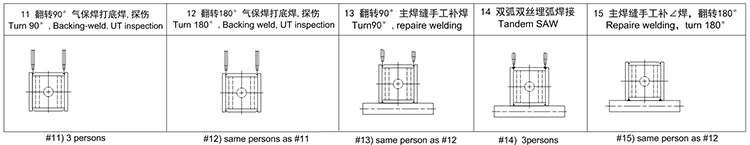

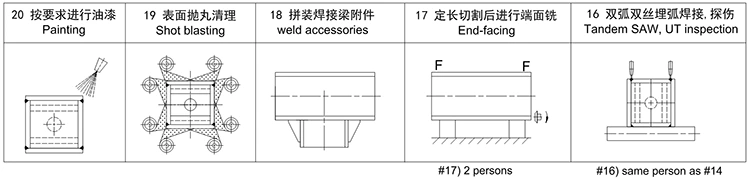

How to produce a weldedBox column from steel plate?

Following is the production flow chart for the production from plates till H beam and final inspection.

Production flow chart