English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

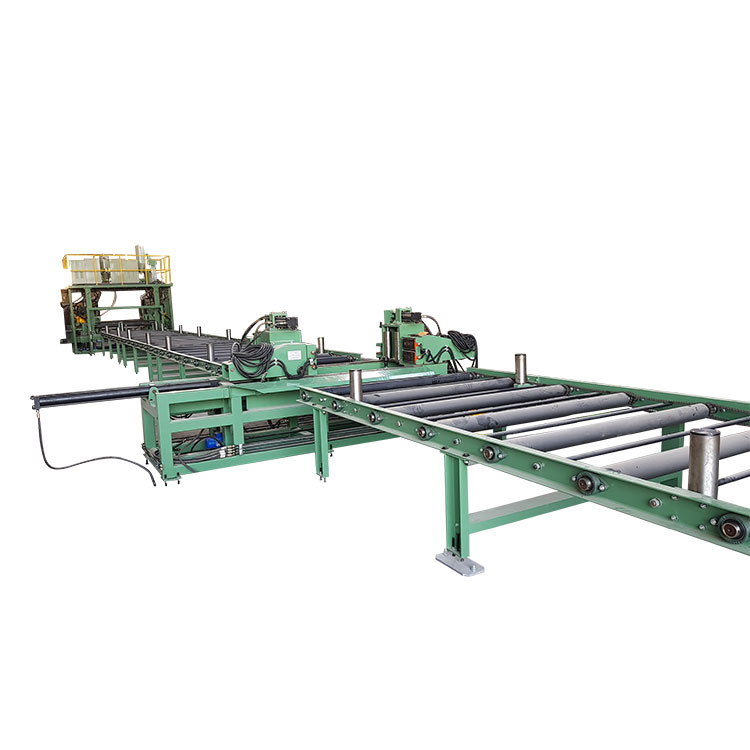

Horizontal H Beam Welding Lines

Send Inquiry

PDF DownLoad

HW Horizontal H beam welding lines

HW15 Horizontal H beam welding lines are high performance H beam production lines combined with different equipments and tool, which are manufactured by JINFENG WELDCUT who is the professional China manufacturer and supplier of HW Horizontal H beam welding lines with affordable price. The HW Horizontal H beam welding lines provide more safety and high efficiency for the H beams or T beam production.

JINFENG WELDCUT will provide have 2 years warranty for the HW Horizontal H beam welding lines. The main electric elements of the H beam productions are selected from the world famous brand that will bring more convenient for Users to find the parts in local without getting from long distance from China. The HW Horizontal H beam welding lines are the most advanced and high automation production lines to increase the productivity for End-users from different industries.

Specifications

|

Model |

HW3015 |

HW2015 |

|

|

H-beam web height |

300-1500mm |

200-1500mm |

|

|

Web thickness |

5-14mm |

5-14mm |

|

|

H-beam flange width |

150-500mm |

150-500mm |

|

|

Flange thickness |

6-25mm |

6-25mm |

|

|

Tapper angle of beam |

Max 15° |

Max 8° |

|

|

H-beam length |

5000-15000mm |

|

|

|

Welding types |

Pre-tack welding by CO2/MAG by hand |

||

|

Full welding by SAW (submerged arc welding) |

|||

|

H beam assembled position |

Horizontal |

||

|

H-beam assembling machine |

1 set, with input and output roller table, for pre-tack welding |

||

|

Pull through H beam welding machine |

1 set, front machine with output roller table, for full welding |

||

|

1 set, rear machine with input and output roller table, for full welding |

|||

|

Chain type H beam overturn machine |

1 set, max loading for 4 tons |

||

Feature And Application

1. HW Horizontal H beam welding lines are high automation production lines to produce the welded I beam and H beam with lesser workers and lesser cranes.

2.High production efficiency for light weight welded beam.

3. One pass welding on 2 welding seams at same time;

4. Need only one type overturning 180 degrees.

5. HW Horizontal H beam welding lines are widely used in steel construction and steel structures for producing H beam to make workshop, warehouse, factory workshop etc.

5. The flexible design of the welding equipments allow to support any brands of the welding power sources.

6. CE, ECA certificated are available.

Structure view

List of the equipments modules used in HW Horizontal H beam welding lines

1-Assembling area, includes:

One horizontal H beam assembling machines with roller table – clamping and fit the 3pcs of plate (1 web and 2 flanges) in H-position and make the web in the center position of 2 flanges. Then the worker can use CO2/MAG welding machine to spot weld the head of the 3 plates at length about 300mm by hand . then open the clamp and the 3pcs of plates with the head pre-welded in H-shape and be transported on roller table to the next welding station.

Assembling H beam in horizontal position

2-Welding area #1, includes:

One sets of pull through welding machine. With one set of web and flanges fixture for fitting the web in the center position of 2 flanges.

The machine here using the twin wire welding technology for full welding with submerged arc welding technology.

Welding H beam in horizontal position

3-H beam overturning, includes:

After full welding on top side of the H beam, the H beam will be moved out from the front pull through H beam welding machines and move to the area for overturning.

The overturning device is a frame with hoisting tools with chains. The chains lifts up the H beam and operate to make the chain moving, thus to make the H beam overturn 180 degrees to let the bottom sides that need welding face upward.

Overturn device

4-Welding area #2, includes:

The pull through welding machine in this area is for welding the H-beam that already have 1 side welding on #1 pull through welding machine.

5-Straightening area.

This is an option machine for the line of horizontal H beam welding line. The Users can select to add one set of mechanical H beam flange straightening after the line, to straighten the flanges of the H beam after welding.

Straightening machine

How to produce a welded H beam/ I beam in horizontal position?

Following is the production flow chart for the production of a welded H beam in horizontal position

Production flow chart

H-beam welding lines installed in Users’ factory