English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

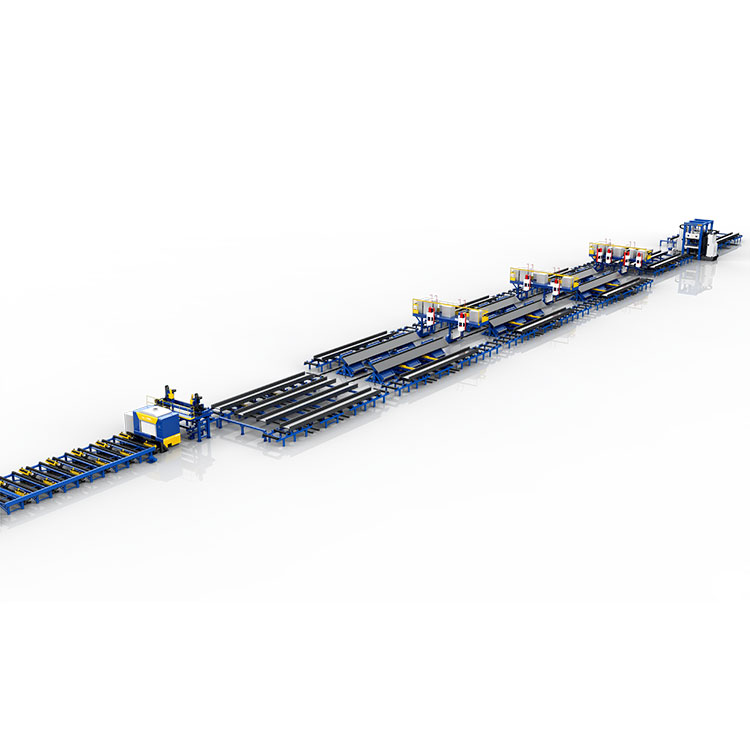

CNC H Beam Welding Lines

Send Inquiry

PDF DownLoad

WH6012 CNC H beam welding lines

WH6012 Smart CNC H beam welding lines are high performance H beam production lines combined with different equipments and tool, which are manufactured by JINFENG WELDCUT who is the professional China manufacturer and supplier of WH6012 Smart CNC H beam welding lines with affordable price. The WH6012 Smart CNC H beam welding lines provide more safety and high efficiency for the H beams or T beam production.

JINFENG WELDCUT will provide have 2 years warranty for the WH6012 Smart CNC H beam welding lines. The main electric elements of the H beam productions are selected from the world famous brand that will bring more convenient for Users to find the parts in local without getting from long distance from China. The WH6012 Smart CNC H beam welding lines are the most advanced and high automation production lines to increase the productivity for End-users from different industries.

Specifications

|

Model |

WH6012 |

WH6012 |

|

Control way |

CNC controlled |

CNC controlled |

|

H-beam web height |

220-1200mm |

220-1200mm |

|

Web thickness |

6-40mm |

6-40mm |

|

H-beam flange width |

1400-800mm |

1400-800mm |

|

Flange thickness |

6-60mm(Q235); 6-40mm (Q345) |

6-60mm(Q345)

|

|

H-beam length |

5000-15000mm |

|

|

Welding types |

Tack welding by CO2/MAG |

|

|

Full welding by SAW |

||

|

H beam assembled position |

Horizontal, tack-weld on 4 welding seams same time |

|

|

H-beam welding position |

Horizontal and tilting at 45° |

|

|

Support data collection for MES |

||

Equipment lists

|

No. |

Name |

Qty |

Remarks |

|

1 |

WHZ6015 H-beam Horizontal assembly machine |

1set |

|

|

2 |

WMH36 H-Beam Automatic SAW welding machine |

1set |

4 arms |

|

WMH36 H-Beam Automatic SAW welding machine |

2set |

2 arms |

|

|

2.1 |

WHJ12 CNC welding positioner |

4set |

|

|

3 |

WJZ6015 H-beam Horizontal straightening machine |

1set |

|

|

4 |

WFZ6012 H-Beam flipper |

2set |

|

|

5 |

WHG6012 Roller table |

6set |

|

|

6 |

WYG12Beam moving cart |

2set |

|

|

7 |

Intelligent data collection management system |

1set |

|

Feature And Application

1.The WH6012 Smart CNC H beam welding lines are high automation production lines to produce the welded I beam and H beam with lesser workers and lesser cranes.

2. Only 3 workers can run the whole CNC H beam welding lines.

3.The line can be fully integration with the MES system and complete the real-time communication between the upper computer and the control system, complete the data collection of the equipment, upload all collected data to the factory MES system (or the upper centralized control system), and ensure the timeliness and effectiveness of information transmission.

4. The design and protection must meet the requirements of relevant national standards and environmental protection; Equipment safety and protective devices must meet relevant industrial standards;.

5.This WH6012 Smart CNC H beam welding lines are widely used in steel construction and steel structures, offshore, onshore, for welding H-beam for making building, workshops, factories, or bridges etc.

6. The flexible design of the welding equipments allow to support any brands of the welding power sources.

6. CE, ECA certificated are available.

7. This line provide the production from light duty beam to very heavy duty beam with big thickness without changing any tools or equipments.

8. From the assembling to the straightening the whole processing no need any cranes, which reduce greatly the risk of using cranes.

Structure view

List of the equipments modules used in WH6012 Smart CNC H beam welding lines

1-Assembling area, includes:

One set of input roller table equipped with flange tilter and web lifter to fit the 2 flanges and 1 web in H- shape position and clamping them in H shape.

One Horizontal H beam assembling machines - for CO2/MAG spot welding to assembly web and flanges in H-shape.

The two flange plates and one web plate to be assembled and formed are hoisted by crane onto the input roller table.

Then as per automatic program, The equipment will lift the web plate, flipping up the two flange plates and clamp the web plate to initially forming an H shape, and then they are transported to the main machine together. Then, the device installed on the machine to align end of the web and flanges, web pressing device, H-beam clamping device, automatic control system and Four sets of welding torches and other components coordinate to work together to quickly complete the assembly of H-beam by spot welding.

Device to lift the web and flip up the flanges

Spot welding on 4 seams at same time

Only one person is required to input or call for the specifications and parameters of the H-beam on the automatic control system and press the start button to start the machine, after the loading of the flange plate and web plate is completed. Therefore, there is less using of crane and high safety performance;

Under the machine is working in normal conditions, after the materials are hoisted on the input roller table, there is no need for manual intervention in the midway of assembling (such as manual positioning, auxiliary leveling of traveling crane, knock correction, lifting, overturning, folding, etc.), so the degree of automation is very high;

Because each key positioning of the H-beam is controlled by the servo motor and detected by the sensor, the accuracy deviation caused by human embarrassment is avoided.

At the same time, all the welding spots of the four welding seam are automatically controlled by the machine, and the uniformity of the welding spot size and spacing is better than that of manual spot welding.

Horizontal H beam assembling machine

2-Welding area

includes:

WHM36 H-Beam Automatic SAW welding machine that is equipped with 4 submerged arc welding heads (supports Single arc welding or tandem arc welding technology).

The equipment consists of two parts: the gantry welding main machine and the multi-position Welding positioner. According to the welding characteristics of H-beam and the process characteristics of tandem arc submerged arc welding, we design two welding modes for this equipment, which is the most special design: "double-arm in flat fillet welding" or "single-arm in fillet welding in the downhand ". The purpose of this design is that the machine can automatically selects the optimal welding mode to realize rapid welding on H-beam, according to the different thickness of webs of H beam. And the multi-position welding table is working with the need of the welding technology /mode to flip the H-beam in different needed angle, thus to achieve the best penetration and welding seam performance. On additional to the multi-position welding table there are 180 degrees beam flipper is working between welding table and roller table, this flipper will help to realize the automatic infeeding of H-beam, and outfeed and the automatic flipping for the welding on different welding seam number.

Welding in horizontal position= flat fillet welding

OR:

WHM36 H-Beam Automatic SAW welding machine that is equipped with 2 submerged arc welding heads (supports Single arc welding or tandem arc welding technology).

WHM36 H-Beam Automatic SAW welding machine

Welding in tilting position= fillet welding in downhand

To work with each SAW welding machine, there are 2sets of CNC welding positioners for each machine to turn the H beam at horizontal or 55 degrees to ensure to have good welding quality.

CNC welding positioner

In the welding area, there are beam flippers to overturn the beam at 90 degrees or 180 degrees for different purposes of welding.

Beam flipper to overturn H beam

The working flow chart of beam flippers:

3-Straightening area, includes:

One set of Beam flipper to overturn the H beam from “H” position to “I” position for the straightening on the flange of beam by straightening machine next.

One H beam flange straightening machines - for straightening the flanges of H beam. One H beam has 2 flanges. Both flanges need straightening. But the machine one time can straighten on one flange. So after complete the straightening of 1 flange, then the beam flipper will overturn the beam at 180 degree to make the flange that need straightening on bottom side.

CNC horizontal straightening machine

How to produce a welded H beam/ I beam from steel plate?

Following is the production flow chart for the production from plates till H beam and final inspection.

Production flow chart

H-beam welding lines installed in Users’ factory