English

English Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

2-1-7 3 In 1 H Beam Welding Line

Send Inquiry

For all the3-in 1 H beam welding lines that manufactured byJINFENG WELDCUT will have 12 months warranty, which are the highest efficiency machine to increase the productivity for End-users from steel structure, bridge, construction.

Specifications

|

Model |

ZHJ15 |

ZHJ18 |

ZHJ20 |

|

T-Beam webHeight (H) |

200~1500mm |

200-1800 |

200-2000mm |

|

Web thickness (d) |

6~12mm |

6~19mm |

6~30mm |

|

Flangewidth (B) |

200~800mm |

200~1000mm |

|

|

Flangethickness (t) |

6~25mm |

6~40mm |

|

|

Beam length (L) |

4000~15000mm |

4000~15000mm |

4000~15000mm |

|

Beam material |

Q235 |

||

|

Welding type |

Submerged arc transverse fillet welding |

||

|

Welding power source |

Single wire or twin wire type |

Single wire |

Single wire |

|

Welding output speed |

200~1000 mm/min |

||

|

Angle of torch: |

45°fine adjustment |

||

|

Hydraulic pressure |

≤14 MPa |

||

|

Flux recovery system |

2sets |

||

|

Volume of flux hopper |

2×50L |

||

|

Input conveyor roller: |

12000 mm |

||

|

Output conveyor roller: |

12000 mm |

||

|

Main Machine power |

18.0kW |

||

|

Hydraulic system: |

1set |

||

|

Straightening unit |

1 set, integrated on machine |

||

|

Power supply: |

AC/380 V/50 Hz/3PH |

||

|

Straightening capability |

6-40mm |

||

Feature And Application

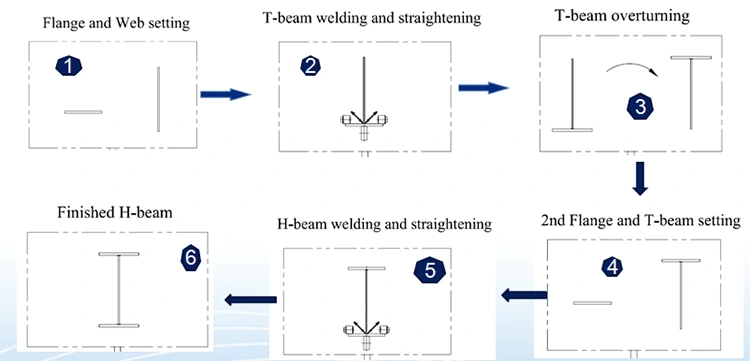

3-in 1 H beam welding lines has as combined function of H beam, T-beam assembly, welding and flange deformation straightening after welding. Thus it can accurately and rapidly realize H beam and T beam production.It has the following advantages: simple operation, less labor cost and small covering area.

This line has two optional welding process for you to choose according to the structural steel plate thickness to be welded:

OPTION A: Single arc twin wire welding of which the deposition rate is 40% higher than the general single arc single wire submerged arc welding, Sot it is especially suitable for the structure steel thickness of which the thickness is less than 20mm.

OPTION B: Single arc single wire welding.It suitable for bigger range of the plate thickness welding.

Details

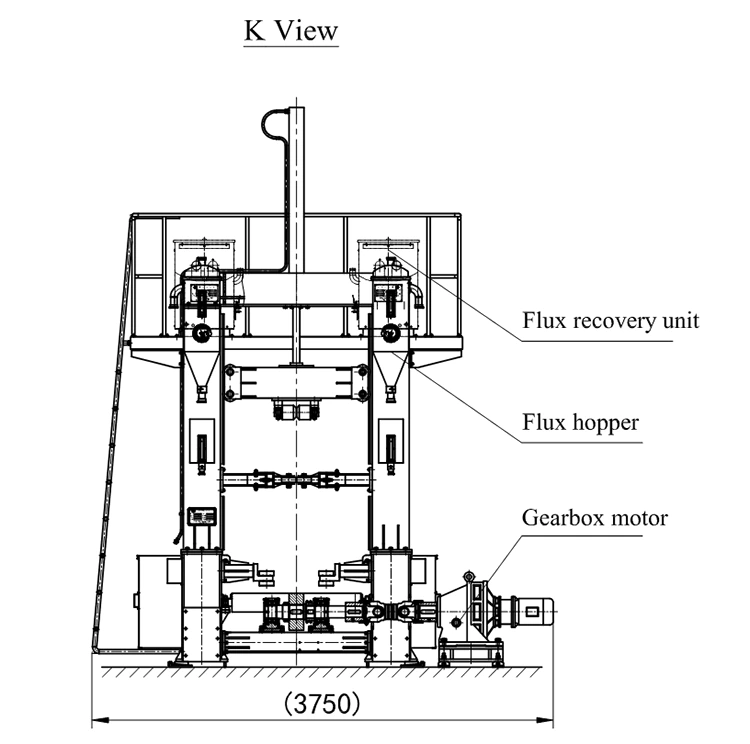

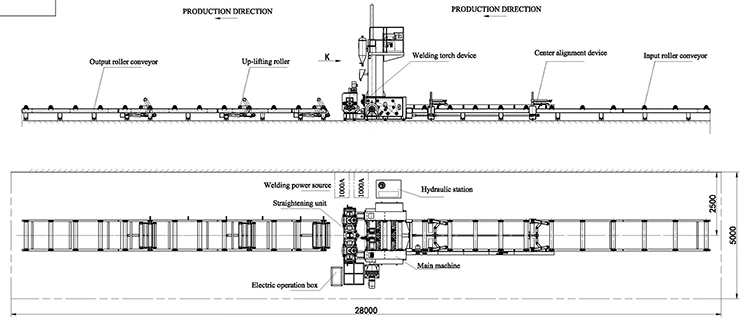

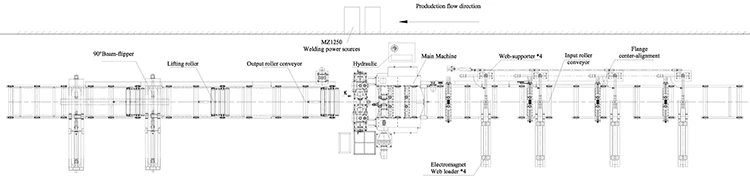

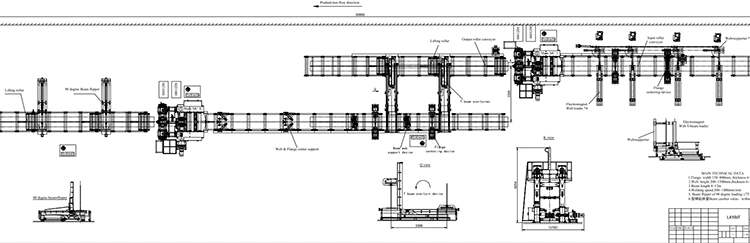

The standard ZHJ3-in 1 H beam welding lines Consists of one input roller table, main welding and straightening station, outputroller table.On the main welding and straightening station there installedwith flux recovery units, welding head with torch and clamping devices for flange and web.The standard line also including the welding power sources, hydraulic station and controloperation box.

1. StandardZHJ3-in 1 H beam welding lines

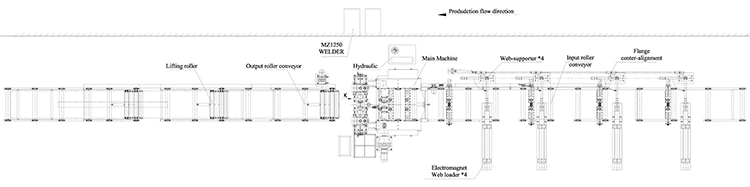

2. OPTION 1:

As per different requests from customers, we also provide the configuration for theZHJ3-in 1 H beam welding lines as the following:

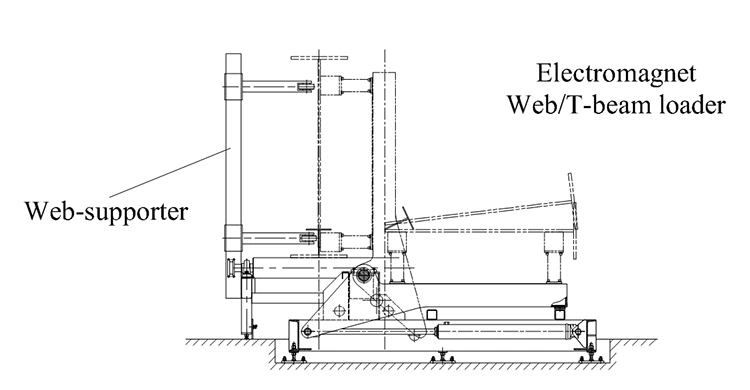

Based on the standard 3-in-1 H beam welding lines, there add one set of web-loader, whichconsists of 4 pcs of magnet loading arm and 4pcs of web supporter.On each web loading arm there are 2pcs of magnet for holding the steel web plate.

3. OPTION 2:

As per different requests from customers, we also provide the configuration for theZHJ3-in 1 H beam welding lines as the following:

Based on the standard 3-in-1 H beam welding lines, there add one set of web-loader, whichconsists of 4 pcs of magnet loading arm and 4pcs of web supporter.On each web loading arm there are 2pcs of magnet for holding the steel web plate.

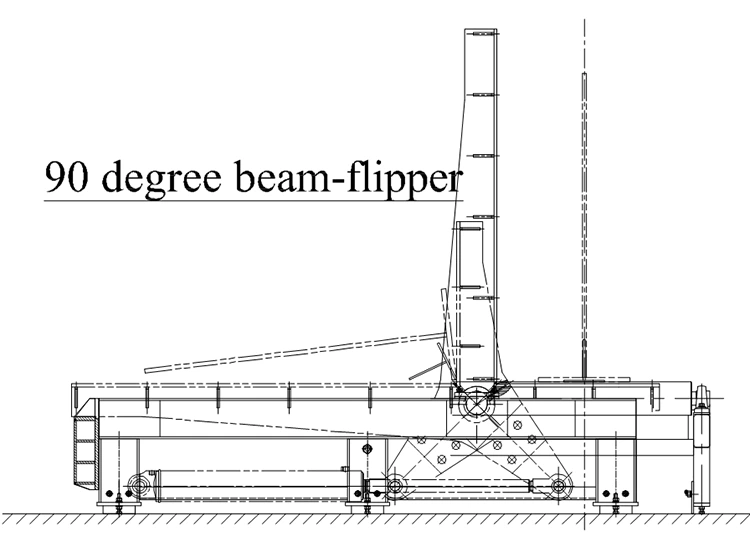

Based on above, we can add one set of 90 degrees beam flipper on the output roller table for overturn the welded beam in horizontal position.

3. OPTION 3:

Some customers may need to increase theproduction output, they need one welding line to consists of 2 sets of welding station.The first welding station for welding 1st flange and web to form a T beam, the 2nd one for welding the welded T-beam and 2nd flange to form a H beam.

3.1 So Based on the standard 3-in-1 H beam welding lines, there add one set of web-loader, whichconsists of 4 pcs of magnet loading arm and 4pcs of web supporter.On each web loading arm there are 2pcs of magnet for holding the steel web plate.

3.2 To add 1 set of T-beam overturner to turning the T-beam in 180 degrees and placing the T-beam on the 2nd flange on the input roller table of 2nd welding station.

3.3 To add one set of 90 degrees beam flipper on the output roller table of2nd welding station for overturn the welded beam in horizontal position.

T beam and H-beam production flow

3-in-1 Integrated H-beam welding lines installed in Users’ factory